Selecting the right semi-hermetic compressor can significantly impact a business’s performance. These compressors play a critical role in ensuring operational efficiency while minimizing energy expenses. For example, industry reports highlight how these systems contribute to cost reduction by analyzing market size, competitors’ shares, and forecasting trends across various regions. A well-matched compressor, such as a semi-hermetic reciprocating compressor, ensures optimal cooling capacity, which is vital for industries like food processing or pharmaceuticals.

An unsuitable compressor, however, can lead to increased downtime, higher maintenance costs, and inefficiencies. Businesses must evaluate their specific needs to avoid these risks and achieve long-term success.

Key takeaway: Choosing the correct semi-hermetic compressor ensures efficiency, cost savings, and business sustainability.

Key Takeaways

- Picking the right semi-hermetic compressor saves energy and money.

- Reciprocating compressors are dependable and flexible, great for exact cooling needs.

- Screw compressors use less energy and work well for big tasks, cutting costs.

- Choosing the right size ensures it cools properly without wasting power.

- Talking to experts helps you avoid errors and pick the best compressor.

Types of Semi-Hermetic Compressors

Reciprocating Semi-Hermetic Compressors

Reciprocating semi-hermetic compressors operate using a piston-cylinder mechanism to compress refrigerants. These compressors are widely recognized for their reliability and versatility. They are particularly effective in applications requiring precise temperature control, such as pharmaceutical storage and laboratory environments. Their modular design allows for easier maintenance and repair, which reduces downtime and operational disruptions.

One of the key advantages of reciprocating compressors is their ability to handle varying load conditions efficiently. This makes them suitable for businesses with fluctuating cooling demands. Additionally, their compact size and robust construction ensure durability, even in demanding industrial settings.

Key takeaway: Reciprocating semi-hermetic compressors offer reliability, precision, and adaptability, making them ideal for industries with specific cooling requirements.

Screw Semi-Hermetic Compressors

Screw semi-hermetic compressors utilize a rotary mechanism with interlocking screws to compress refrigerants. These compressors excel in applications requiring continuous operation and high cooling capacities, such as large-scale food processing facilities and industrial manufacturing plants. Their design minimizes vibration and noise, creating a quieter workplace environment.

Energy efficiency is a significant advantage of screw compressors. They often achieve higher coefficients of performance (COP), which translates to reduced energy consumption and lower operational costs. Furthermore, their ability to handle large volumes of refrigerant makes them a preferred choice for businesses prioritizing sustainability and cost-effectiveness.

Key takeaway: Screw semi-hermetic compressors deliver high efficiency and performance, making them suitable for large-scale and energy-intensive applications.

Industry Applications of Semi-Hermetic Compressors

Semi-hermetic compressors play a vital role across various industries. Their applications range from food storage and processing to pharmaceutical manufacturing and industrial refrigeration. Businesses increasingly invest in these compressors to meet energy efficiency and sustainability goals. For example, the focus on higher COP values has driven the adoption of advanced compressor technologies.

The following table highlights key trends in the industrial applications of semi-hermetic compressors:

| Trend | Description |

|---|---|

| Energy Efficiency | Increasing focus on higher coefficient of performance (COP) values to reduce energy consumption. |

| Sustainability | Adoption driven by environmental regulations and the need for sustainable refrigeration solutions. |

| Food Safety and Quality | Growing investment in advanced refrigeration systems to ensure proper food storage and handling. |

| Innovations in Compressor Design | Development of advanced technologies to improve reliability and reduce maintenance requirements. |

| Heat Recovery Systems | Integration of cooling and heating solutions in sectors like food processing and industrial manufacturing. |

These trends underscore the growing importance of semi-hermetic compressors in achieving operational efficiency and compliance with environmental standards.

Key takeaway: Semi-hermetic compressors are indispensable in industries prioritizing energy efficiency, sustainability, and advanced refrigeration solutions.

Key Factors to Consider When Choosing a Semi-Hermetic Compressor

Cooling Capacity and Sizing Requirements

Selecting the correct cooling capacity is critical when choosing a semi-hermetic compressor. A system that is too small may struggle to meet cooling demands, leading to inefficiencies and potential equipment failure. Conversely, an oversized compressor can result in unnecessary energy consumption and higher operational costs. Businesses must evaluate their specific cooling requirements based on factors such as the size of the facility, the type of application, and the expected load variations.

Proper sizing ensures that the compressor operates within its optimal performance range. For example, industries like food processing often require precise temperature control to maintain product quality. In such cases, a semi-hermetic compressor with adjustable capacity can provide the flexibility needed to handle varying cooling loads efficiently.

Key takeaway: Accurate sizing of a semi-hermetic compressor ensures optimal performance, energy efficiency, and reduced operational costs.

Energy Efficiency and Operational Costs

Energy efficiency plays a pivotal role in reducing operational costs. Compressors account for a significant portion of energy consumption in refrigeration systems, making it essential to prioritize models with high efficiency. Modern semi-hermetic compressors often feature advanced technologies, such as variable speed drives, which adjust the compressor’s output to match real-time cooling demands. This reduces energy waste and lowers utility bills.

Recent case studies highlight the financial benefits of energy-efficient compressors:

- Fixing leaks in compressed air systems can prevent 31% of energy use, leading to substantial cost savings.

- Businesses implementing leak inspection and repair programs have reported annual savings of approximately $25,355.95.

- Reducing excessive energy costs associated with compressed air utilities enhances overall profitability.

Investing in energy-efficient compressors not only reduces costs but also aligns with sustainability goals. By minimizing energy consumption, businesses can lower their carbon footprint and contribute to environmental conservation.

Key takeaway: Energy-efficient semi-hermetic compressors reduce operational costs and support sustainability initiatives.

Refrigerant Compatibility and Environmental Compliance

Refrigerant compatibility is another crucial factor when selecting a semi-hermetic compressor. The choice of refrigerant impacts the system’s performance, environmental compliance, and long-term viability. Businesses must consider refrigerants with low Global Warming Potential (GWP) to meet environmental regulations and reduce greenhouse gas emissions.

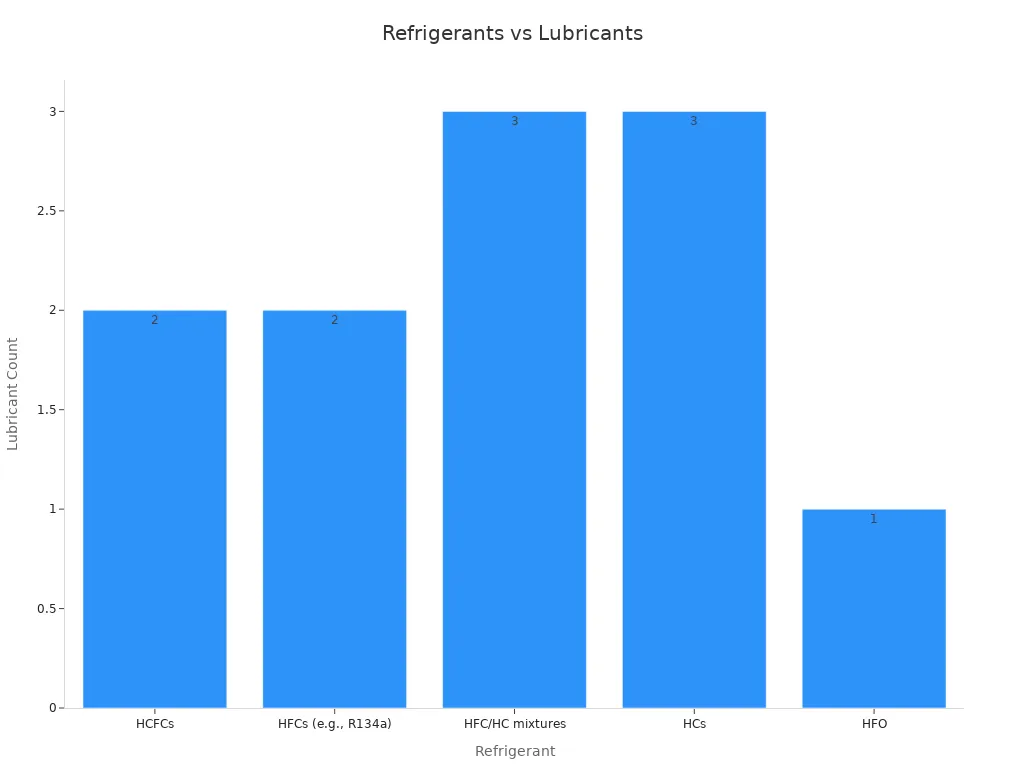

The following table outlines the compatibility of various refrigerants with recommended lubricants:

| Refrigerant | Recommended Lubricants |

|---|---|

| HCFCs | MO and AB |

| HFCs (e.g., R134a) | PAG and POI |

| HFC/HC mixtures | MO, AB, and POE |

| HCs | MO, AB, and POE |

| HFO | PAG |

The industry’s shift towards low-GWP refrigerants reflects growing environmental concerns. Regulations like the Kyoto Protocol and the EU’s F-Gas Regulation have driven this transition. In 2012, refrigerants accounted for 130 million metric tonnes of CO2 equivalents in the EU, underscoring the need for sustainable alternatives.

Key takeaway: Choosing refrigerants compatible with semi-hermetic compressors ensures environmental compliance and supports sustainability efforts.

Noise Levels and Workplace Environment

Noise levels play a crucial role in determining the suitability of a semi-hermetic compressor for a business environment. Excessive noise can disrupt workplace productivity, affect employee well-being, and even violate local noise regulations. Therefore, businesses must evaluate the acoustic performance of compressors before making a purchase.

Factors Influencing Noise Levels

Several factors contribute to the noise generated by a semi-hermetic compressor:

- Compressor Design: Compressors with advanced engineering often feature noise-reducing components, such as sound-dampening enclosures and vibration isolation systems.

- Operating Conditions: High-speed operations or heavy loads can increase noise levels. Compressors designed for consistent performance under varying conditions tend to produce less noise.

- Installation Environment: Poor installation practices, such as inadequate mounting or improper alignment, can amplify vibrations and noise.

Importance of Noise Control in the Workplace

Minimizing noise is essential for maintaining a productive and comfortable workplace. Studies show that prolonged exposure to high noise levels can lead to stress, fatigue, and reduced concentration among employees. In industries like food processing or pharmaceutical manufacturing, where precision and focus are critical, a quieter compressor can significantly enhance operational efficiency.

Additionally, businesses operating in urban or residential areas must comply with noise regulations to avoid penalties. Selecting a compressor with low decibel ratings ensures compliance while fostering positive relationships with neighboring communities.

Noise Reduction Strategies

To address noise concerns, businesses can implement the following strategies:

- Choose Low-Noise Compressors: Opt for models specifically designed to operate quietly. Many modern semi-hermetic compressors incorporate noise-reducing technologies.

- Install Acoustic Barriers: Use soundproofing materials or barriers around the compressor to contain noise within the designated area.

- Regular Maintenance: Ensure that all components, such as bearings and seals, are in optimal condition. Worn-out parts can increase noise levels over time.

- Optimize Placement: Position the compressor in a location that minimizes noise transmission to workspaces or external environments.

Tip: Consult with manufacturers or experts to identify compressors that meet both performance and noise requirements.

Summary of Key Points

Noise levels directly impact workplace productivity, employee well-being, and regulatory compliance. Businesses should prioritize compressors with low noise emissions and implement effective noise control measures. By addressing these factors, they can create a more efficient and harmonious work environment.

Installation and Maintenance Considerations for Semi-Hermetic Compressors

Location and Ventilation Needs

The placement of a semi-hermetic compressor significantly impacts its performance and lifespan. Proper location ensures optimal airflow, which is essential for maintaining efficient heat dissipation. Compressors generate heat during operation, and inadequate ventilation can lead to overheating, reducing efficiency and increasing the risk of equipment failure.

To address ventilation needs, businesses should install compressors in areas with sufficient space for air circulation. Avoid placing the unit near walls or other equipment that could obstruct airflow. Additionally, ensure the location is free from dust, debris, and moisture, as these elements can compromise the compressor’s functionality. Installing ventilation systems or exhaust fans can further enhance airflow and maintain a stable operating environment.

Tip: Conduct a site assessment to identify the best location for your compressor, considering factors like airflow, temperature, and environmental conditions.

Accessibility for Repairs and Servicing

Routine maintenance and timely repairs are crucial for the efficient operation of a semi-hermetic compressor. Accessibility plays a key role in simplifying these tasks. Compressors should be installed in locations that allow technicians to easily access critical components, such as valves, filters, and electrical connections.

When planning the installation, businesses should consider the space required for tools and equipment used during servicing. Clear pathways and adequate lighting can further facilitate maintenance activities. Proper accessibility not only reduces downtime but also minimizes labor costs associated with complex repair procedures.

Key takeaway: Strategic placement of compressors ensures easy access for maintenance, reducing operational disruptions and extending equipment life.

Longevity and Durability Factors

The durability of a semi-hermetic compressor depends on several factors, including material quality, operating conditions, and maintenance practices. High-quality compressors, such as those manufactured by reputable companies, are designed to withstand demanding industrial environments. However, even the most durable units require proper care to achieve their maximum lifespan.

To enhance longevity, businesses should adhere to recommended maintenance schedules, including regular inspections, lubrication, and part replacements. Monitoring operating conditions, such as temperature and pressure, can help identify potential issues before they escalate. Additionally, investing in protective measures, such as vibration dampeners and surge protectors, can safeguard the compressor from external damage.

Key takeaway: Regular maintenance and protective measures ensure the long-term durability of semi-hermetic compressors, maximizing return on investment.

Real-World Example: Installation Success in a Food Processing Facility

A prominent food processing facility faced challenges maintaining consistent cooling for its perishable products. The facility required a reliable refrigeration system to ensure food safety and quality. After evaluating various options, the management selected a semi-hermetic screw compressor due to its high cooling capacity and energy efficiency.

The installation process began with a thorough site assessment. Engineers identified an optimal location that provided adequate ventilation and minimized noise impact on the workspace. The compressor was installed with sound-dampening enclosures to ensure compliance with local noise regulations. Technicians also incorporated advanced monitoring systems to track performance metrics, such as temperature and pressure, in real time.

Post-installation, the facility experienced significant improvements. The semi-hermetic compressor maintained precise temperature control, ensuring the freshness of stored products. Its energy-efficient design reduced electricity consumption by 20%, leading to substantial cost savings. Additionally, the quiet operation of the compressor enhanced the workplace environment, allowing employees to focus on their tasks without distractions.

The facility’s management also implemented a proactive maintenance schedule. Regular inspections and timely servicing ensured the compressor operated at peak efficiency. This approach minimized downtime and extended the equipment’s lifespan, maximizing the return on investment.

Key takeaway: The successful installation of a semi-hermetic compressor in a food processing facility demonstrates the importance of proper planning, strategic placement, and regular maintenance. Businesses can achieve enhanced operational efficiency, cost savings, and compliance with industry standards by selecting the right compressor and following best practices.

Professional Guidance in Selecting Semi-Hermetic Compressors

Benefits of Expert Consultation

Consulting with industry professionals can significantly enhance the process of selecting a semi-hermetic compressor. Experts bring specialized knowledge and experience, enabling businesses to make informed decisions tailored to their operational needs. For instance, an air audit conducted by a compressed air professional can identify inefficiencies, optimize system performance, and extend the lifespan of the equipment. Companies that have undergone such audits often report substantial cost savings, as highlighted in the white paper, How an Air Compressor Audit Can Help You Build Competitive Advantage.

Building long-term relationships with trusted service providers also proves beneficial. One manufacturer, for example, secured a favorable repair arrangement during an airend failure due to their established partnership with a service organization. This underscores the importance of trust and expertise in service relationships. Additionally, selecting a provider with a deep understanding of operations ensures effective maintenance and timely service, supported by responsive local infrastructure.

Key takeaway: Professional consultation minimizes risks, optimizes performance, and ensures long-term cost savings.

Choosing a Reliable Manufacturer or Supplier

Selecting a reliable manufacturer or supplier is crucial for ensuring the quality and compliance of a semi-hermetic compressor. Reputable manufacturers adhere to regulatory standards, which is essential for safety and environmental considerations. Their customer-centric strategies allow them to customize products to meet the unique requirements of various industries, enhancing customer satisfaction.

Strategic partnerships with reliable manufacturers often lead to innovative solutions. These collaborations address diverse customer needs, providing businesses with a competitive edge. For example, manufacturers with a strong focus on research and development can offer advanced technologies that improve energy efficiency and operational reliability.

Key takeaway: Partnering with a reliable manufacturer ensures compliance, innovation, and tailored solutions for business success.

Real-World Example: Avoiding Costly Mistakes with Professional Advice

A pharmaceutical company faced challenges maintaining precise temperature control in its storage facilities. Initially, the company selected a compressor without consulting experts, leading to frequent breakdowns and increased operational costs. Recognizing the need for professional guidance, the management engaged a team of refrigeration specialists.

The experts conducted a thorough assessment of the facility’s requirements and recommended a semi-hermetic compressor with advanced temperature control features. They also provided guidance on proper installation and maintenance practices. Post-implementation, the company experienced a 30% reduction in energy costs and improved product quality due to consistent temperature regulation.

This case highlights the value of professional advice in avoiding costly mistakes. By leveraging expert insights, businesses can select the right equipment, optimize performance, and achieve long-term savings.

Key takeaway: Professional advice helps businesses avoid costly errors, ensuring optimal equipment performance and operational efficiency.

Understanding the different types of semi-hermetic compressors and their applications is essential for making informed decisions. Proper selection and installation ensure operational efficiency, cost savings, and long-term reliability. Businesses benefit significantly from consulting professionals who provide tailored advice and solutions. Partnering with reputable manufacturers guarantees access to high-quality products and innovative technologies.

Evaluating specific business needs is the first step toward success. By seeking expert guidance, companies can avoid costly mistakes and achieve optimal performance. Investing in the right semi-hermetic compressor is a strategic move that drives growth and sustainability.

Key takeaway: Careful planning, professional advice, and quality equipment are the cornerstones of a successful refrigeration system.

FAQ

What is the primary advantage of using a semi-hermetic compressor?

Semi-hermetic compressors offer superior energy efficiency and durability. Their design allows for easier maintenance and repair, reducing downtime. These features make them ideal for industries requiring reliable and cost-effective refrigeration solutions.

Tip: Regular maintenance ensures optimal performance and extends the lifespan of semi-hermetic compressors.

How do I determine the right size of a semi-hermetic compressor for my business?

Evaluate your cooling requirements based on facility size, application type, and load variations. Proper sizing ensures the compressor operates efficiently without overloading or wasting energy.

Key takeaway: Accurate sizing prevents inefficiencies and reduces operational costs.

Are semi-hermetic compressors compatible with eco-friendly refrigerants?

Yes, many semi-hermetic compressors support low-GWP refrigerants, aligning with environmental regulations. Compatibility depends on the compressor model and refrigerant type.

| Refrigerant Type | Compatibility |

|---|---|

| HFCs | High |

| HFOs | Moderate |

Note: Consult manufacturers for specific refrigerant compatibility.

How can I reduce noise levels in my compressor system?

Choose compressors with noise-reducing features like sound-dampening enclosures. Proper installation, including vibration isolation and acoustic barriers, minimizes noise impact.

Tip: Position compressors away from workspaces to enhance employee comfort.

Why is professional consultation important when selecting a compressor?

Experts provide tailored advice based on your operational needs. They help identify the right compressor, ensure proper installation, and optimize performance, reducing costly errors.

Key takeaway: Professional guidance enhances efficiency and ensures long-term savings.

Send your message to us:

Post time: Apr-24-2025