8 Years Exporter Rotary Screw Compressor - Semi-Hermetic Reciprocating Compressor R22 R404A R134A R507A 2YD-2.2-2YG-4.2 – Daming Refrigeration Technology Detail:

1. ZheJiang DaMing Refrigeration Technology Co., Ltd. Profile

- Business Type: We are Manufacturer/Factory/Plant

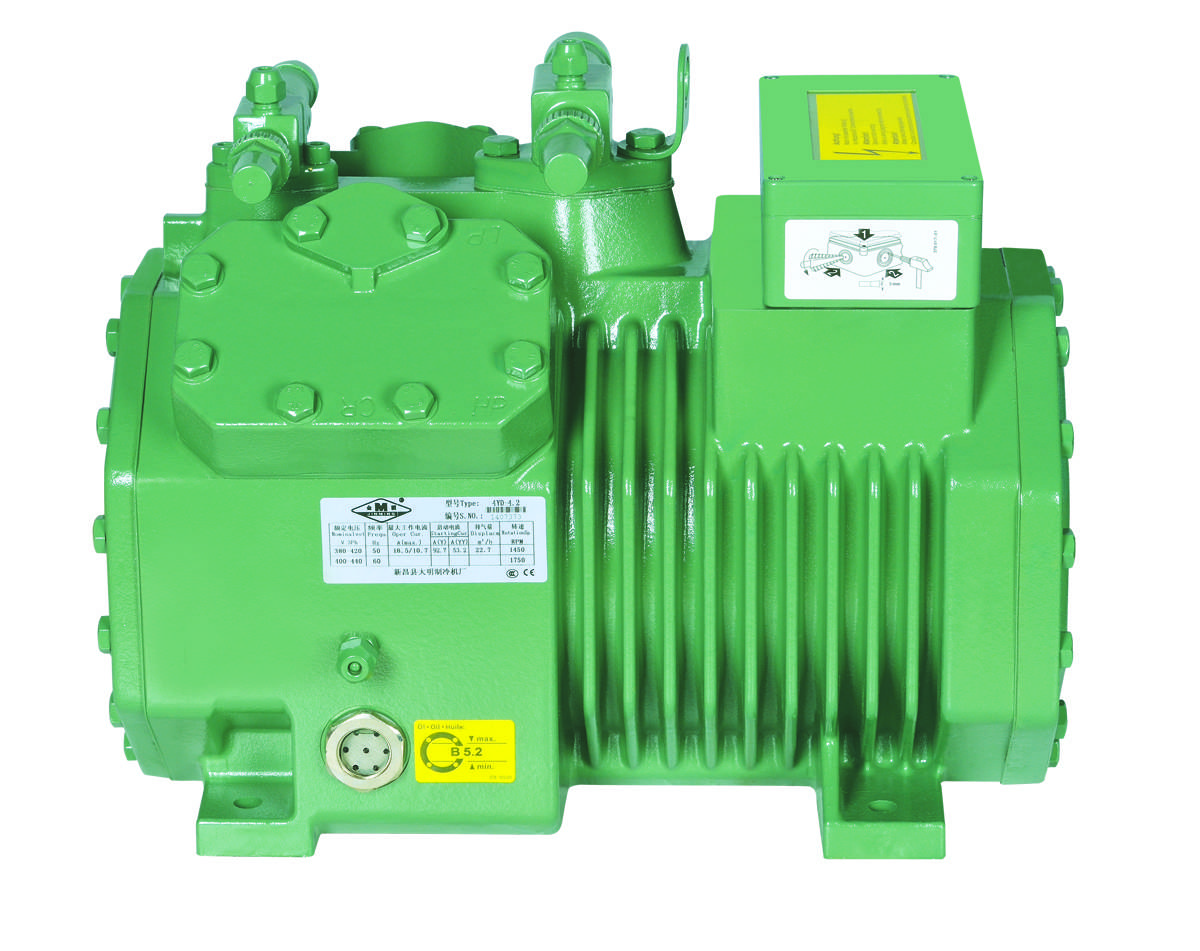

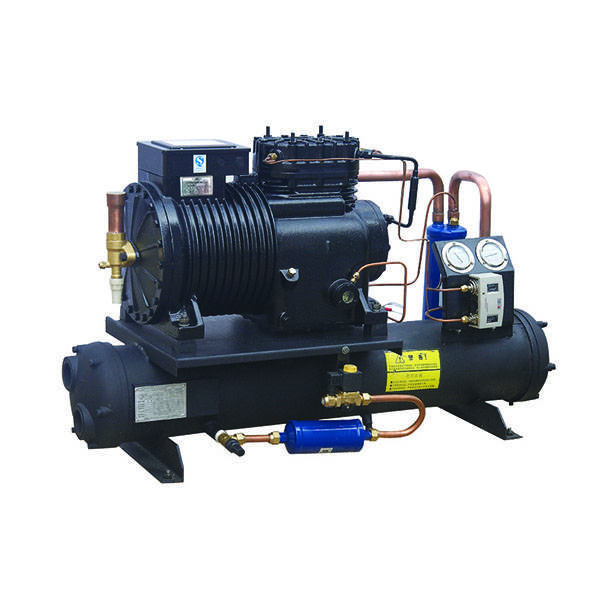

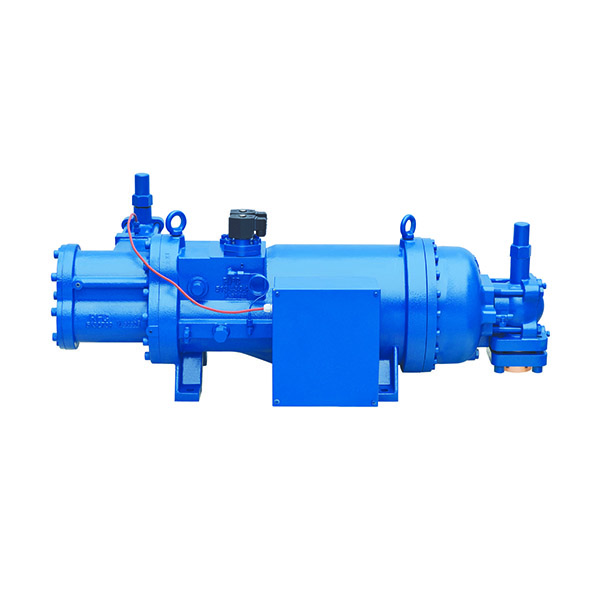

- Main Products: compressor ,compressor unit .(reciprocating compressor, scroll compressor, screw compressor)

- Number of Employees: 300+

- Year of Establishment: 1990s

- Management System Certification: ISO 9001

- Location: ZheJiang, China (Mainland)

2. Basic Information

- Series: 2YD-2.2-2YG-4.2 Explanation of model designation

- Compressor Body Material: Iron 2/4/6 ———————Cylinders

- Application : Refrigeration Y/V/W ———————-Model

- Refrigeration gas: R22, R404A,R134A,R507A

- Input Voltage: 3Ф 380V-420V/50HZ;440V-480V/60HZ

- Origin: Zhejiang, China D/G———————D for Low Temp;G for mid & High Temp

- Specification: CE, CCC,ISO9001 2 ———————–Horse Power

- 2 ———————–Series Code

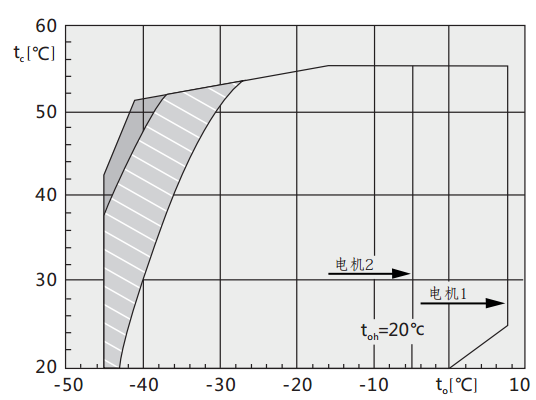

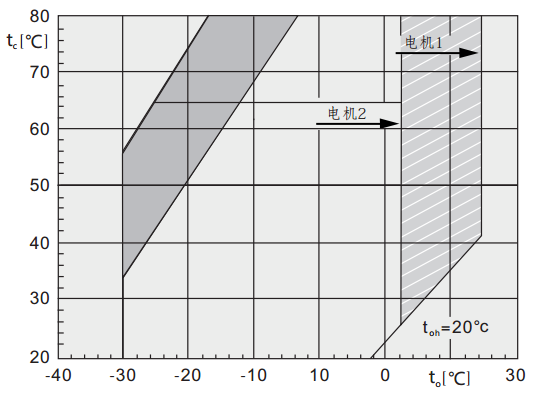

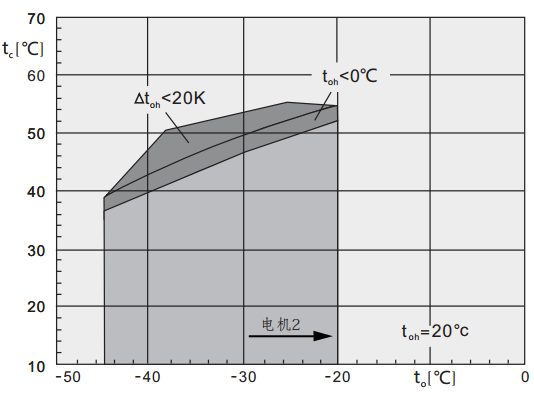

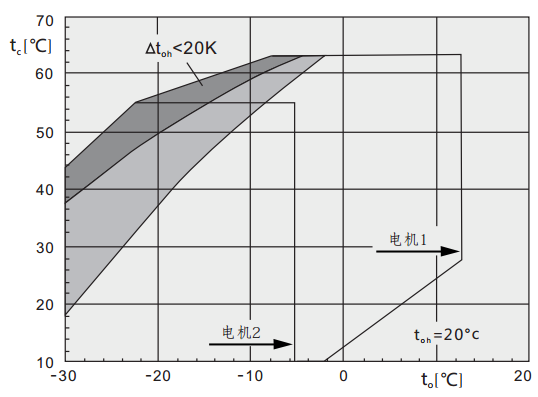

3. Application Limits ( Suction Gas Temperature 20°C)

R404A & R507A

R134A

R22(Air cooling)

Suction gas Cooling

To —— Evaporating temperature(°C)

Toh —- Suction gas temperature(°C)

Toh —- Suction super heat(K)

Tc ——-Condensing temperature(°C)

Additional cooling

Additional cooling

Additional cooling&limited suction gas temperature

Additional cooling&liquid injection cooling system

4.Product Details

4.1 Key Specifications/Special Features -Technical Data Sheet

| Model | Nominal Power

HP/KW |

Displacement

m³/h 50Hz |

Number of

Cylinders× Diameter× Stoke |

Exhaust & Suction Valve mm/IN | Oil Volume

(L) |

Power

V/φ/Hz |

Electrical Parameter | Crankcase

Heater (220V)W |

Oil Supply

Method |

Weight

(Including Oil) Kg |

||

| DL Exhaust

Valve |

SL Suction

Valve |

Max Operating

Current(A) |

Starting/ Locked

Current(A) |

|||||||||

| 2YD-2.2 | 2/1.5 | 13.4 | 2×Φ50×39.3 | φ16 | φ22 | 1.5 | 220-240△/380-420Y/3/50 265-290△/440-480Y/3/60 | 11.9/6.9 | 53.7/30.7 | 120 | Centrifugal

lubrication |

67.5 |

| 2YG-3.2 | 3/2.2 | 13.4 | 2×Φ50×39.3 | φ16 | φ22 | 1.5 | 13.5/7.8 | 64/37 | 120 | 70.5 | ||

| 2YD-3.2 | 3/2.2 | 16.2 | 2×Φ55×39.3 | φ16 | φ22 | 1.5 | 14.8/8.5 | 64/37 | 120 | 70 | ||

| 2YG-4.2 | 4/3 | 16.2 | 2×Φ55×39.3 | φ16 | φ22 | 1.5 | 16.4/9.4 | 76.6/44.2 | 120 | 70 | ||

4.2 Refrigerating Performance – Cooling Capacity with R22

| Model | Condensing

Temperature℃ |

Cooling Capacity Qo(W) Power Consumption Pe(kW) | |||||||||||||

| Evaporating Temperature ℃ | |||||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | |||

| 2YD-2.2 | 30 | Qo | 9110 | 7430 | 5980 | 5150 | 4030 | 3100 | 2330 | 1700 | |||||

| Pe | 2.42 | 2.39 | 2.14 | 2.02 | 1.82 | 1.62 | 1.43 | 1.24 | |||||||

| 40 | Qo | 7970 | 6430 | 5110 | 4370 | 3370 | 2550 | 1870 | 1330 | ||||||

| Pe | 2.77 | 2.57 | 2.35 | 2.22 | 1.97 | 1.73 | 1.49 | 1.26 | |||||||

| 50 | Qo | 6790 | 5400 | 4200 | 3520 | 2660 | 1960 | 1390 | |||||||

| Pe | 3.08 | 2.80 | 2.53 | 2.40 | 2.09 | 1.850 | 1.54 | ||||||||

| 2YG-3.2 | 30 | Qo | 17280 | 15860 | 14530 | 13290 | 11060 | 9120 | 7440 | 5990 | 4740 | 3670 | 2770 | ||

| Pe | 2.01 | 2.14 | 2.24 | 2.31 | 2.36 | 2.33 | 2.24 | 2.09 | 1.92 | 1.74 | 1.58 | ||||

| 40 | Qo | 15400 | 14110 | 12910 | 11780 | 9750 | 7980 | 6450 | 5120 | 3970 | 3000 | 2160 | |||

| Pe | 2.89 | 2.92 | 2.93 | 2.92 | 2.84 | 2.69 | 2.50 | 2.28 | 2.06 | 1.86 | 1.70 | ||||

| 50 | Qo | 13490 | 12320 | 11230 | 10220 | 8380 | 6780 | 5390 | 4190 | 3160 | 2270 | ||||

| Pe | 3.64 | 3.59 | 3.52 | 3.44 | 3.23 | 2.98 | 2.72 | 2.45 | 2.20 | 2.00 | |||||

| 2YD-3.2 | 30 | Qo | 11350 | 9290 | 7500 | 6390 | 5040 | 3890 | 2940 | 2160 | |||||

| Pe | 2.85 | 2.74 | 2.56 | 2.40 | 2.15 | 1.91 | 1.70 | 1.49 | |||||||

| 40 | Qo | 9880 | 8010 | 6380 | 5400 | 4160 | 3140 | 2290 | 1600 | ||||||

| Pe | 3.32 | 3.07 | 2.79 | 2.56 | 2.27 | 2.00 | 1.74 | 1.47 | |||||||

| 50 | Qo | 8370 | 6680 | 5230 | 4450 | 3340 | 2430 | 1680 | |||||||

| Pe | 3.73 | 3.39 | 3.04 | 2.79 | 2.46 | 2.19 | 1.90 | ||||||||

| 2YG-4.2 | 30 | Qo | 21400 | 19650 | 18020 | 16490 | 13750 | 11360 | 9290 | 7510 | 5970 | 4660 | 3550 | ||

| Pe | 2.48 | 2.63 | 2.74 | 2.83 | 2.91 | 2.88 | 2.78 | 2.61 | 2.40 | 2.17 | 1.93 | ||||

| 40 | Qo | 18960 | 17380 | 15910 | 14540 | 12050 | 9890 | 8020 | 6390 | 5000 | 3800 | 2780 | |||

| Pe | 3.67 | 3.69 | 3.68 | 3.64 | 3.51 | 3.31 | 3.06 | 2.79 | 2.51 | 2.24 | 2.01 | ||||

| 50 | Qo | 16490 | 15080 | 13760 | 12520 | 10290 | 8350 | 6670 | 5210 | 3960 | 2880 | ||||

| Pe | 4.61 | 4.51 | 4.40 | 4.27 | 3.99 | 3.67 | 3.33 | 3.01 | 2.72 | 2.47 | |||||

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | |||||||||||||||

| VARICOOL system,additional cooling,position of suction valve changed. | |||||||||||||||

| Additional cooling or limited suction gas temperature. | |||||||||||||||

| Additional cooling and CIC system. | |||||||||||||||

Refrigerating Performance - Cooling Capacity with R404A,R507A

| Model | Condensing

Temperature℃ |

Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||||||

| Evaporating Temperature ℃ | ||||||||||||||

| 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| 2YD-2.2 | 30 | Qo | 10110 | 8340 | 6810 | 5490 | 4360 | 3390 | 2570 | 1880 | 1300 | |||

| Pe | 2.72 | 2.59 | 2.43 | 2.25 | 2.05 | 1.83 | 1.59 | 1.35 | 1.09 | |||||

| 40 | Qo | 8490 | 68980 | 5670 | 4530 | 3560 | 2720 | 2020 | 1420 | 920 | ||||

| Pe | 3.15 | 2.94 | 2.7 | 2.44 | 2.17 | 1.88 | 1.58 | 1.28 | 0.98 | |||||

| 50 | Qo | 6900 | 5640 | 4550 | 3600 | 2780 | 2080 | 1490 | 990 | |||||

| Pe | 3.55 | 3.25 | 2.93 | 2.59 | 2.25 | 1.9 | 1.54 | 1.19 | ||||||

| 2YG-3.2 | 30 | Qo | 15940 | 14630 | 12260 | 10200 | 8420 | 6870 | 5540 | 4400 | 3420 | 2590 | 1890 | |

| Pe | 2.79 | 2.8 | 2.77 | 2.71 | 2.6 | 2.45 | 2.28 | 2.08 | 1.86 | 1.62 | 1.37 | |||

| 40 | Qo | 13510 | 12390 | 10380 | 8610 | 7080 | 5750 | 4600 | 3610 | 2760 | 2040 | 1430 | ||

| Pe | 3.49 | 3.44 | 3.32 | 3.16 | 2.96 | 2.74 | 2.49 | 2.21 | 1.92 | 1.62 | 1.31 | |||

| 50 | Qo | 11110 | 10180 | 8500 | 7030 | 5740 | 4630 | 3660 | 2820 | 2110 | 1510 | 1000 | ||

| Pe | 4.11 | 4.02 | 3.8 | 3.55 | 3.27 | 2.96 | 2.63 | 2.29 | 1.93 | 1.57 | 1.2 | |||

| 2YD-3.2 | 30 | Qo | 12470 | 10290 | 8400 | 6780 | 5380 | 4190 | 3180 | 2330 | 1630 | |||

| Pe | 3.33 | 3.15 | 2.95 | 2.72 | 2.48 | 2.21 | 1.93 | 1.64 | 1.35 | |||||

| 40 | Qo | 10510 | 8650 | 7040 | 5640 | 4440 | 3420 | 2550 | 1810 | 1200 | ||||

| Pe | 3.85 | 3.58 | 3.29 | 2.98 | 2.65 | 2.32 | 1.97 | 1.62 | 1.27 | |||||

| 50 | Qo | 8590 | 7050 | 5710 | 4550 | 3540 | 2690 | 1950 | 1340 | |||||

| Pe | 4.35 | 3.98 | 3.60 | 3.21 | 2.80 | 2.39 | 1.98 | 1.57 | ||||||

| 2YG-4.2 | 30 | Qo | 19440 | 17840 | 14960 | 12450 | 10280 | 8400 | 6770 | 5380 | 4190 | 3170 | 2320 | |

| Pe | 3.48 | 3.48 | 3.42 | 3.32 | 3.17 | 2.98 | 2.76 | 2.50 | 2.23 | 1.94 | 1.64 | |||

| 40 | Qo | 16470 | 15110 | 12660 | 10520 | 8660 | 7050 | 5650 | 4450 | 3420 | 2540 | 1810 | ||

| Pe | 4.31 | 4.25 | 4.08 | 3.86 | 3.61 | 3.33 | 3.02 | 2.69 | 2.34 | 1.98 | 1.61 | |||

| 50 | Qo | 13550 | 12430 | 10400 | 8620 | 7070 | 5720 | 4550 | 3540 | 2690 | 1960 | 1340 | ||

| Pe | 5.08 | 4.96 | 4.68 | 4.36 | 4.01 | 3.63 | 3.23 | 2.82 | 2.40 | 1.98 | 1.55 | |||

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | ||||||||||||||

| Additional cooling or limited suction gas temperature. | ||||||||||||||

| Additional cooling and CIC system. | ||||||||||||||

Refrigerating Performance - Cooling Capacity with r134a

| Model | Condensing

Temperature℃ |

Cooling Capacity Qo(W) Power Consumption Pe(kW) | |||||||||||

| Evaporating Temperature ℃ | |||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | |||

| 2YD-2.2 | 30 | Qo | 11730 | 10680 | 9710 | 8810 | 7200 | 5820 | 4650 | 3660 | 2820 | 2120 | 1540 |

| Pe | 1.82 | 1.79 | 1.75 | 1.71 | 1.63 | 1.53 | 1.43 | 1.31 | 1.18 | 1.03 | 0.87 | ||

| 40 | Qo | 10320 | 9390 | 8530 | 7730 | 6300 | 5070 | 4030 | 3140 | 2390 | 1760 | 1240 | |

| Pe | 2.15 | 2.11 | 2.06 | 2.01 | 1.89 | 1.76 | 1.62 | 1.46 | 1.28 | 1.09 | 0.88 | ||

| 50 | Qo | 8950 | 8150 | 7390 | 6690 | 5440 | 4360 | 3440 | 2660 | 1990 | 1430 | 970 | |

| Pe | 2.47 | 2.41 | 2.35 | 2.28 | 2.13 | 1.96 | 1.78 | 1.58 | 1.36 | 1.12 | 0.86 | ||

| 2YG-3.2 | 50 | Qo | 8930 | 8120 | 7370 | 6670 | 5420 | 4350 | 3430 | 2650 | 1990 | ||

| Pe | 2.41 | 2.35 | 2.29 | 2.22 | 2.07 | 1.91 | 1.74 | 1.54 | 1.33 | ||||

| 60 | Qo | 7670 | 6980 | 6320 | 5720 | 4630 | 3700 | 2890 | 2210 | 1630 | |||

| Pe | 2.70 | 2.62 | 2.54 | 2.46 | 2.28 | 2.09 | 1.87 | 1.64 | 1.38 | ||||

| 70 | Qo | 6460 | 5860 | 5310 | 4800 | 3870 | 3070 | 2390 | 1810 | 1310 | |||

| Pe | 3.00 | 2.90 | 2.80 | 2.70 | 2.49 | 2.25 | 2.00 | 1.71 | 1.41 | ||||

| 2YD-3.2 | 30 | Qo | 14820 | 13510 | 12290 | 11150 | 9130 | 7400 | 5920 | 4670 | 3610 | 2720 | 1980 |

| Pe | 2.19 | 2.15 | 2.11 | 2.06 | 1.95 | 1.83 | 1.69 | 1.54 | 1.37 | 1.19 | 1.00 | ||

| 40 | Qo | 13050 | 11880 | 10800 | 9790 | 8000 | 6450 | 5130 | 4010 | 3070 | 2270 | 1610 | |

| Pe | 2.62 | 2.56 | 2.50 | 2.43 | 2.27 | 2.11 | 1.92 | 1.72 | 1.50 | 1.27 | 1.03 | ||

| 50 | Qo | 11340 | 10320 | 9370 | 8490 | 6910 | 5550 | 4390 | 3400 | 2570 | 1860 | 1280 | |

| Pe | 302 | 2.94 | 2.85 | 2.76 | 2.56 | 2.35 | 2.11 | 1.86 | 1.60 | 1.32 | 1.02 | ||

| 2YG-4.2 | 50 | Qo | 11300 | 10280 | 9340 | 8460 | 6890 | 5540 | 4380 | 3400 | 2570 | ||

| Pe | 3.03 | 2.95 | 2.86 | 2.76 | 2.56 | 2.34 | 2.10 | 1.85 | 1.58 | ||||

| 60 | Qo | 6960 | 8810 | 8000 | 7230 | 5870 | 4690 | 3680 | 2830 | 2100 | |||

| Pe | 3.39 | 3.28 | 3.17 | 3.06 | 2.81 | 2.54 | 2.26 | 1.96 | 1.65 | ||||

| 70 | Qo | 8140 | 7390 | 6700 | 6050 | 4890 | 3890 | 3040 | 2310 | 1700 | |||

| Pe | 3.75 | 3.61 | 3.48 | 3.34 | 3.04 | 2.73 | 2.40 | 2.06 | 1.70 | ||||

| Suction gas temperature 20℃,50Hz,without liquid subcooling. | |||||||||||||

| Additional cooling or limited suction gas temperature. | |||||||||||||

4.3 Processing Features

The compressors of Daming suit different working condition and refrigerants,and could maximally satisfy your requirements for the refrigerating system.

The compressors of Daming suit different working condition and refrigerants,and could maximally satisfy your requirements for the refrigerating system.

Developed technology,compact dimension ,Small volume and space .

High precision machining to ensure the compressor confirm with the standard ,CNC processing center ,Concentricity due to specific processing technology ,minimal dead space .

High precision machining to ensure the compressor confirm with the standard ,CNC processing center ,Concentricity due to specific processing technology ,minimal dead space .

Steady operation,small vibracation and low noise ,Excellent stability .

Refrigerant like R22 and R404 are adopted to protect the environment ,For mid & low temperature application .

Electrical motor protect device ,PTC sensor .

Wear resistant driver gear ,Chrome plated piston rings and aluminium pistons ,Hardened crank-shaft ,Low friction bearing set .

Efficient valve plate design,high refrigerating capacity and low energy consumption ,Efficient compression rate ,Valve reed made of imported impact resistant spring steel .

Efficient valve plate design,high refrigerating capacity and low energy consumption ,Efficient compression rate ,Valve reed made of imported impact resistant spring steel .

General spare parts,convenient for maintenance.

4.4 Cross Reference (Application Limits )

|

Cross Reference |

||||

|

Item Description |

Daming Model |

Copeland Model |

Bitzer Model |

Displacement (KW) |

|

2 cylinders |

BFS31 |

C-0300 |

12.2 |

|

|

BFS41 |

C-0400 |

14.7 |

||

|

BFS51 |

C-0500 |

18.4 |

||

|

BFS81 |

C-0800 |

26.6 |

||

|

BFS101 |

C-1000 |

36 |

||

|

3 cylinders |

BFS151 |

C-1500 |

54 |

|

|

4 cylinders |

4S151D |

4SLW-1500 |

73.6 |

|

|

4S251G |

4SHH-2500 |

73.6 |

||

|

4S201D |

4STW-2000 |

84.5 |

||

|

4S301G |

4STH-3000 |

84.5 |

||

|

6 cylinders |

6S251D |

6SLW-2500 |

110.5 |

|

|

6S351G |

6SHH-3500 |

110.5 |

||

|

6S321D |

6STW-3200 |

126.8 |

||

|

6S401G |

6SJH-4000 |

126.8 |

||

|

6S401D |

6SUW-4000 |

151.6 |

||

|

6S501G |

6SKH-5000 |

151.6 |

||

|

Small size 2 cylinders |

2YD-2.2 |

2DC-2.2 |

13.5 |

|

|

2YG-3.2 |

2DC-3.2 |

13.5 |

||

|

2YD-3.2 |

2CC-3.2 |

16.2 |

||

|

2YG-4.2 |

2CC-4.2 |

16.2 |

||

|

Small size 4 cylinder ( hexagon shape) |

4YD-3.2 |

4FC-3.2 |

18.1 |

|

|

4YG-5.2 |

4FC-5.2 |

18.1 |

||

|

4YD-4.2 |

4EC-4.2 |

22.7 |

||

|

4YG-6.2 |

4EC-6.2 |

22.7 |

||

|

4YD-5.2 |

4DC-5.2 |

26.84 |

||

|

4YG-7.2 |

4DC-7.2 |

26.84 |

||

|

4YD-6.2 |

4CC-6.2 |

32.48 |

||

|

4YG-9.2 |

4CC-9.2 |

32.48 |

||

|

Medium size 4 cylinders (hexagon shape ) |

4YD-8.2 |

4TCS-8.2 |

41.33 |

|

|

4YG-12.2 |

4TCS-12.2 |

41.33 |

||

|

4YD-10.2 |

4PCS-10.2 |

48.5 |

||

|

4YG-15.2 |

4PCS-15.2 |

48.5 |

||

|

4YD-12.2 |

4NCS-12.2 |

56.25 |

||

|

4YG-20.2 |

4NCS-20.2 |

56.25 |

||

|

Large 4 cylinders |

4VD-15.2 |

4H-15.2 |

73.6 |

|

|

4VG-25.2 |

4H-25.2 |

73.6 |

||

|

4VD-20.2 |

4G-20.2 |

84.5 |

||

|

4VG-30.2 |

4G-30.2 |

84.5 |

||

|

Large 6 cylinders |

6WD-25.2 |

6H-25.2 |

110.5 |

|

|

6WG-35.2 |

6H-35.2 |

110.5 |

||

|

6WD-30.2 |

6G-30.2 |

126.8 |

||

|

6WG-40.2 |

6G-40.2 |

126.8 |

||

|

6WD-40.2 |

6F-40.2 |

151.6 |

||

|

6WG-50.2 |

6F-50.2 |

151.6 |

||

|

Double stage |

6WDS-20.2 |

S6H-20.2 |

110.5 |

|

|

6WDS-25.2 |

S6G-25.2 |

126.8 |

||

|

6WDS-30.2 |

S6F-30.2 |

151.6 |

||

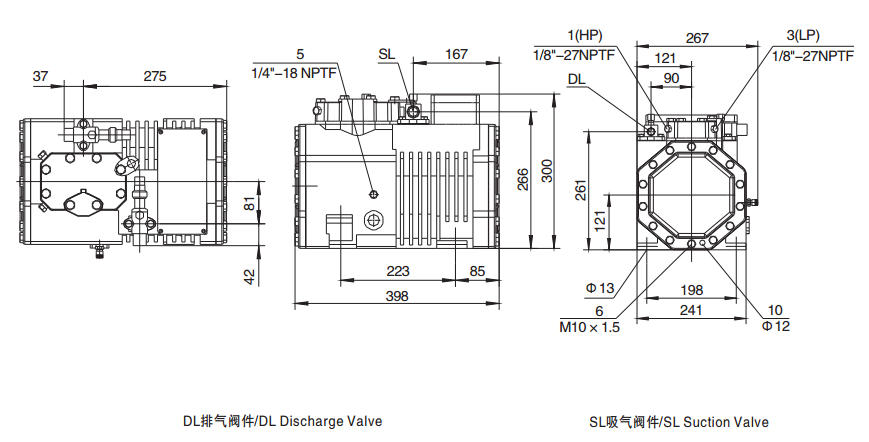

4.5 Compressor Dimensional drawing

4.6 Packaging & Shipment

- FOB Port: Ningbo Lead Time:15- 30 days

- Packaging Size: 49*44*15 cm Net weight: 62 kg +

- Units per Export Carton:1 Gross weight: 70 kg +

- Dimensions per Unit:193 × 94 × 87 Centimeters

- Weight per Unit:117 Kilograms

- Export Carton Weight: 117 Kilograms

- Export Carton Dimensions L/W/H:193 × 94 × 87 Centimeters

5. Payment & Delivery

- Payment Method: Advance TT, T/T, L/C.

- Delivery Details: within 30-50 days after receiving your full payment .

3.7 Primary Competitive Advantage

- Small Orders Accepted Brand-name Parts Country of Origin

- Distributorships Offered Electronic Link Experienced Staff

- Form A Green Product Cost-effective

- International Approvals Military Specifications Standard Packaging

- Good Price Product Features Product Performance

- Prompt Delivery Quality Approvals Reputation

- Provide Good Service Sample Available Customized

- We have over 30 years of professional experience as a manufacturer of semi-hermetic compressor , scroll compressor , screw compressor ,condensing unit .

- We make the compressor according your usage

- We have strong researching and developing team to meet your requirement.

- There are lot of raw material suppliers around our factory, our factory in Zhejiang

- We supply high quality compressor for many world companies

- Our factory got ISO 9001 and apply CE certificate, importantly we have factory which bigger workshop over 20000sq meters .

- Small trial orders can be accepted, sample is available .

- Our price is reasonable and keep top quality for every clients.

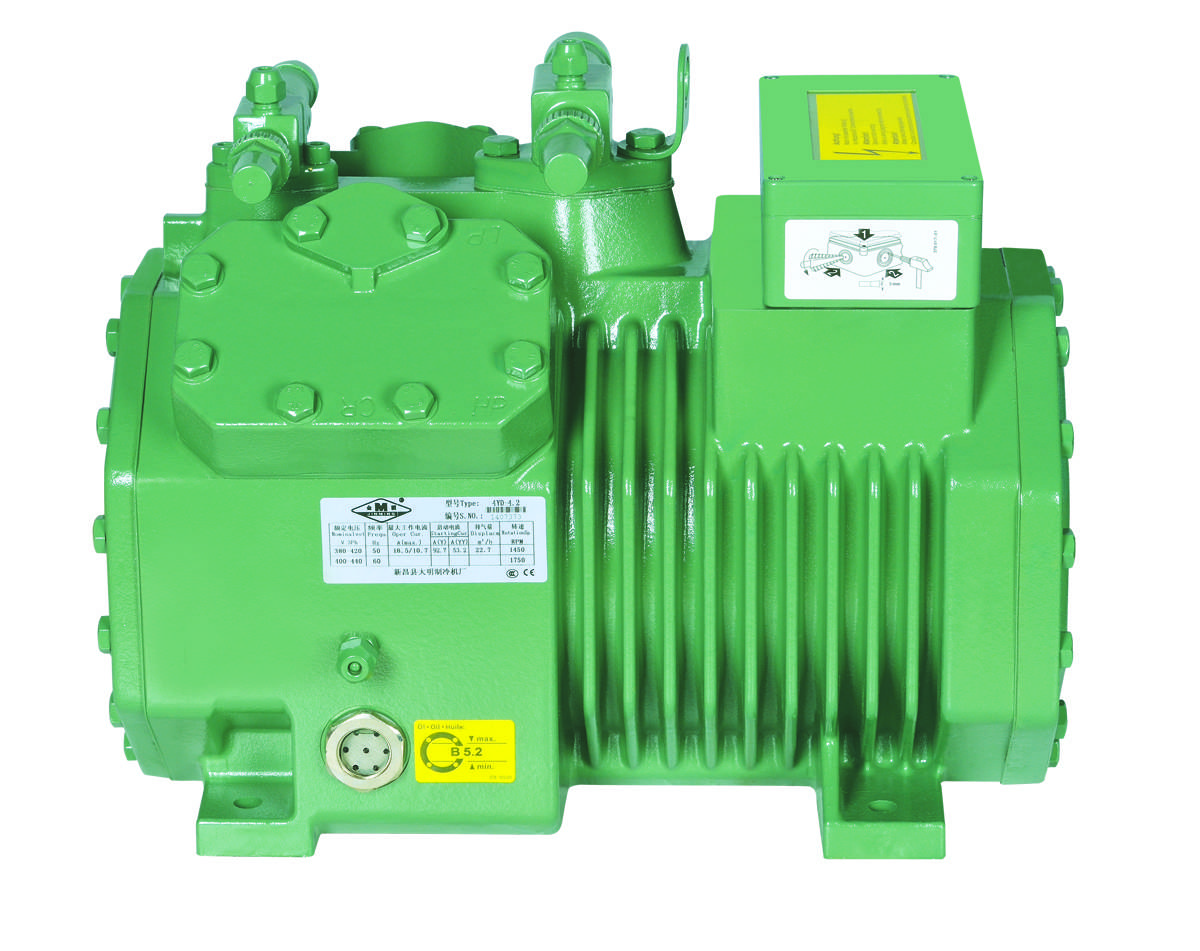

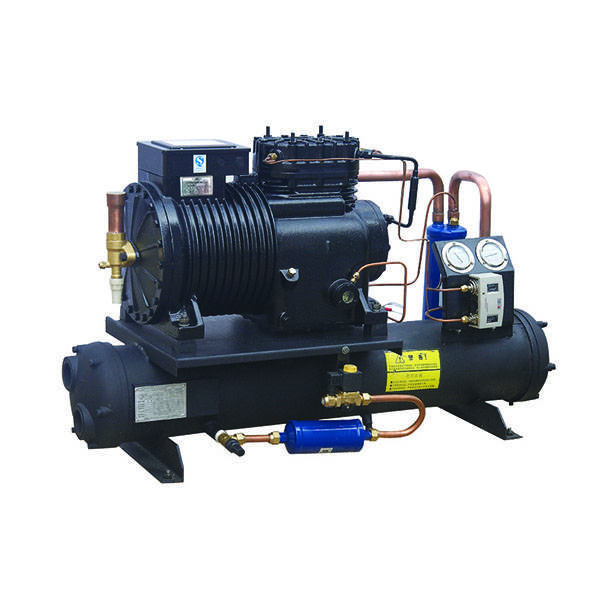

Product detail pictures:

Related Product Guide:

What Are the Advantages of Using a Reciprocating Compressor?

Shengzhou Mayor visited Daming

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with 8 Years Exporter Rotary Screw Compressor - Semi-Hermetic Reciprocating Compressor R22 R404A R134A R507A 2YD-2.2-2YG-4.2 – Daming Refrigeration Technology, The product will supply to all over the world, such as: America, Qatar, Auckland, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

-

Wholesale Discount Copeland Semi Hermetic Compr...

-

Factory making Diesel Engine Portable Compresso...

-

ODM Factory China Car Compressor - Semi-Hermet...

-

Hot sale 2dc-3.2 Compressor - Semi-hermetic &#...

-

2018 wholesale price Air Compressor 2 Cylinder ...

-

China New Product Cryogenic Refrigerator Compre...